In the project ‘Going Eco, Going Dutch’ the focus was on the circular use of natural fibres. It was intended to use a combination of locally grown hemp and recycled postconsumer cotton. The mechanical recycling was using discarded garments, which are collected and sorted in The Netherlands.

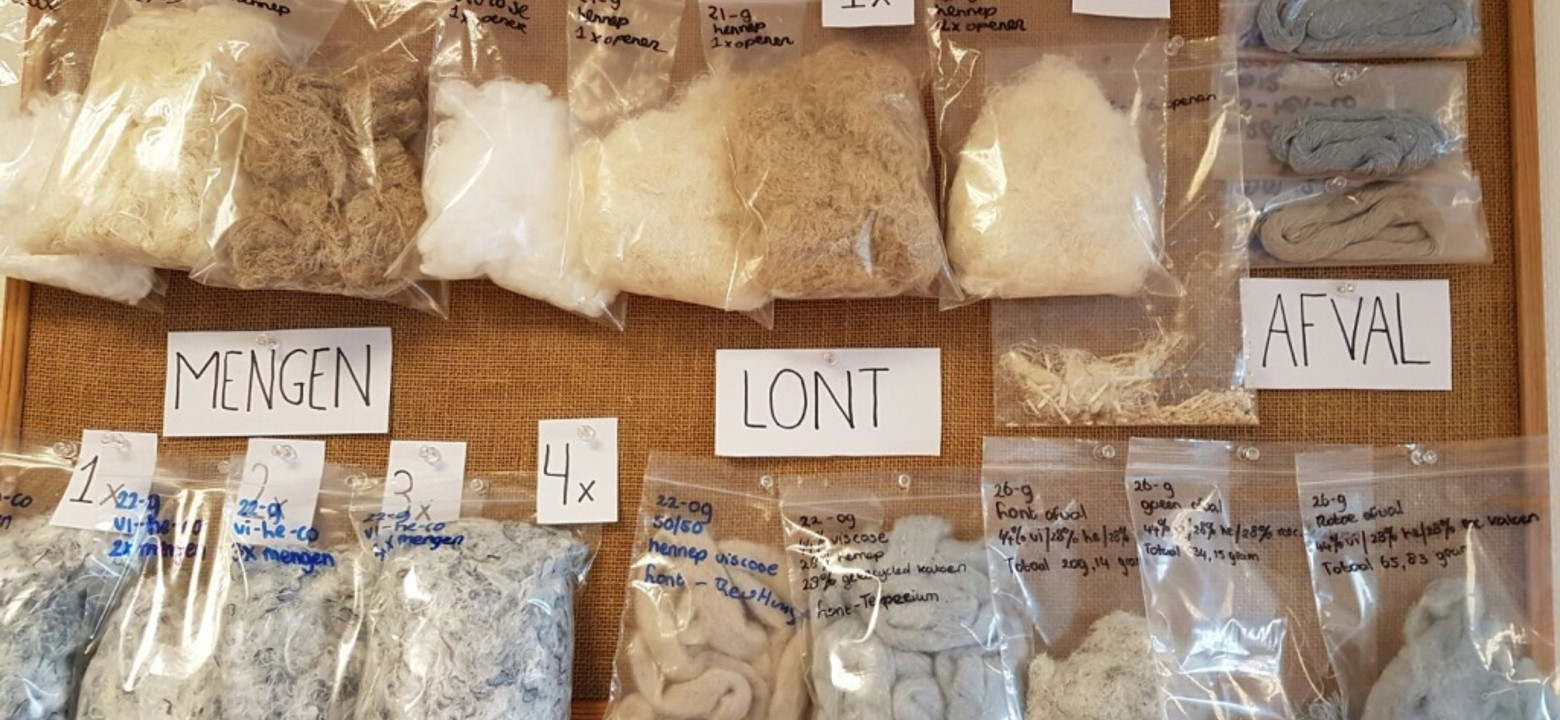

Going Eco, Going Dutch focused on upcycling of recycled textile in combination with alternative fibres such as hemp, – in which locality played an important role. The fibers were locally processed into yarns and used to produce woven and knitted fabrics by researchers and textile companies within the project. Textile waste needed for sustainable yarn development is widely available. However, the fibers of the recycled content were short and the local hemp fibers used in this project were at that time still too short and there was limited availability. When developing a quality yarn, a blend of different kind of (virgin) fibres was needed. The produced yarns were irregular: but designers could use this aspect as an advantage and unique selling point instead of a disadvantage.

It was a two- year project in which the educational institutions ArtEZ University of the Arts and Saxion University of applied sciences were in the lead. In the project consortium different stakeholders from the Dutch textile and fashion industry worked together to realize the circular supply chain.

The project brought together local textile manufacturers, suppliers, designers and fashion experts in order to find and test new ways of local sustainable production methods and circular design principles. Through an interdisciplinary approach, this project combined a scientific study and technical exploration of textiles, design research and creative practice. In developing a local circular economy, all actors in the supply chain worked together to develop new sustainable fabrics for applications in the fashion industry.

Results

Different fabrics were produced with a quality sufficient for non-demanding fashion applications. There is no additional dyeing needed. The project showed that sustainable and local production chains lead to appealing, high quality, environmentally friendly and sustainable textile products.

For more information about this project contact Theresia Grevinga [email protected]